3D-Printed Low-Profile Single-Substrate Multi-Metal Layer Antennas and Array With Bandwidth Enhancement

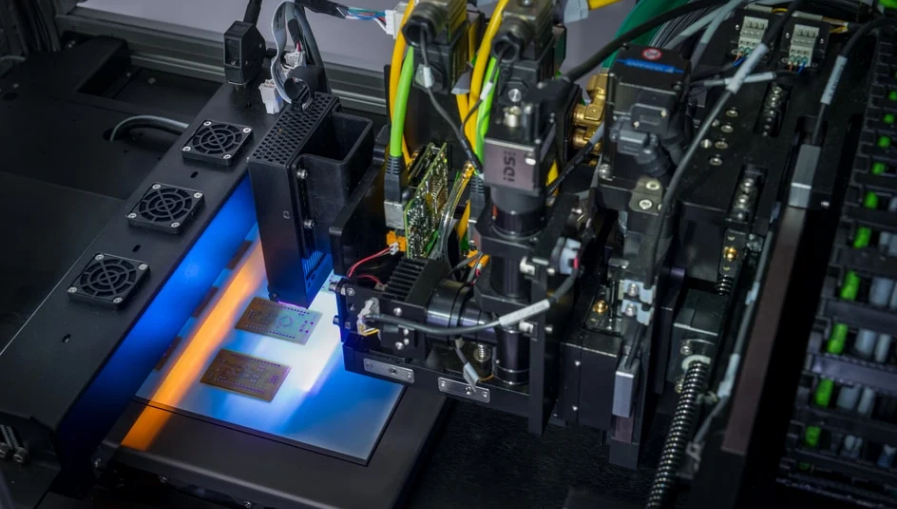

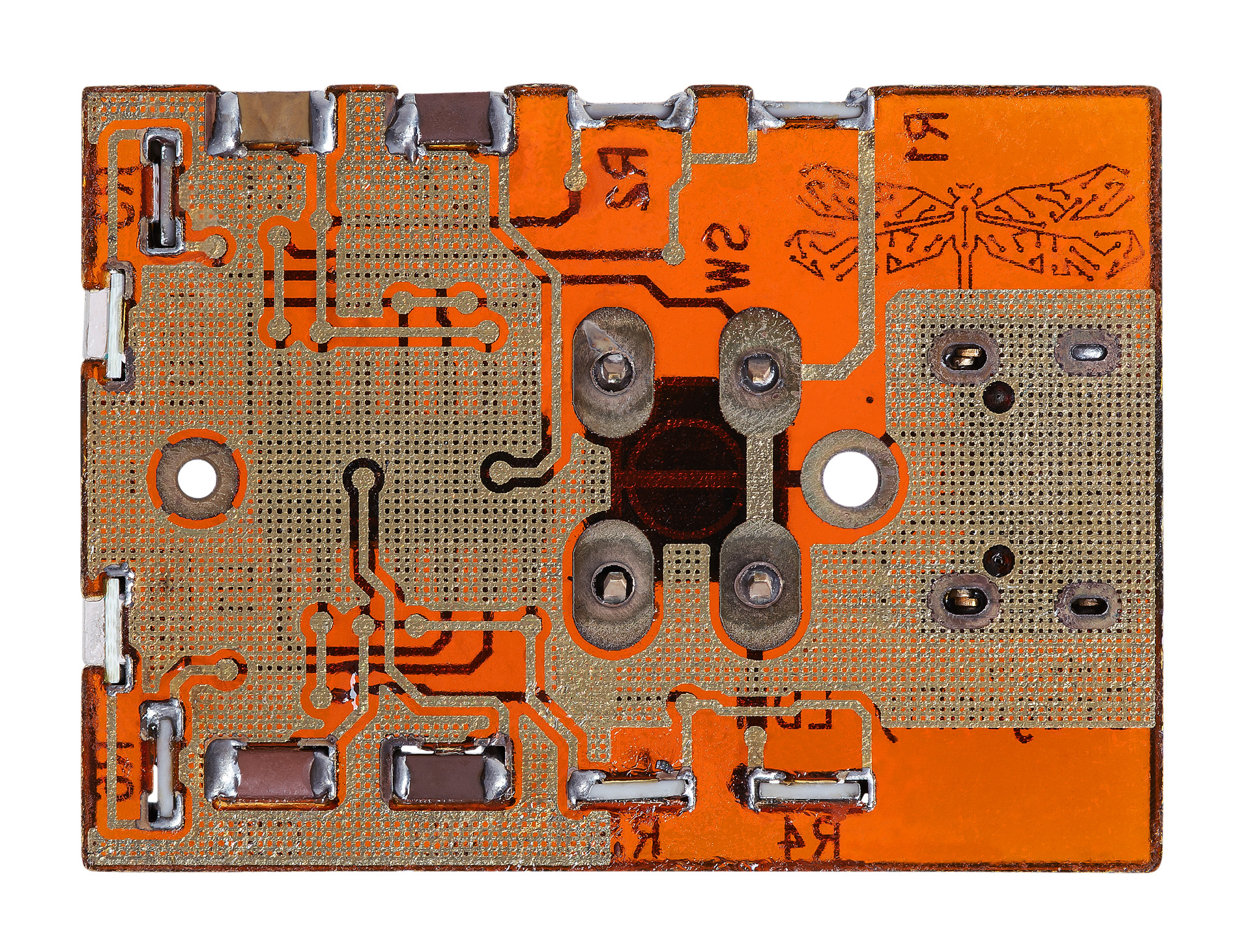

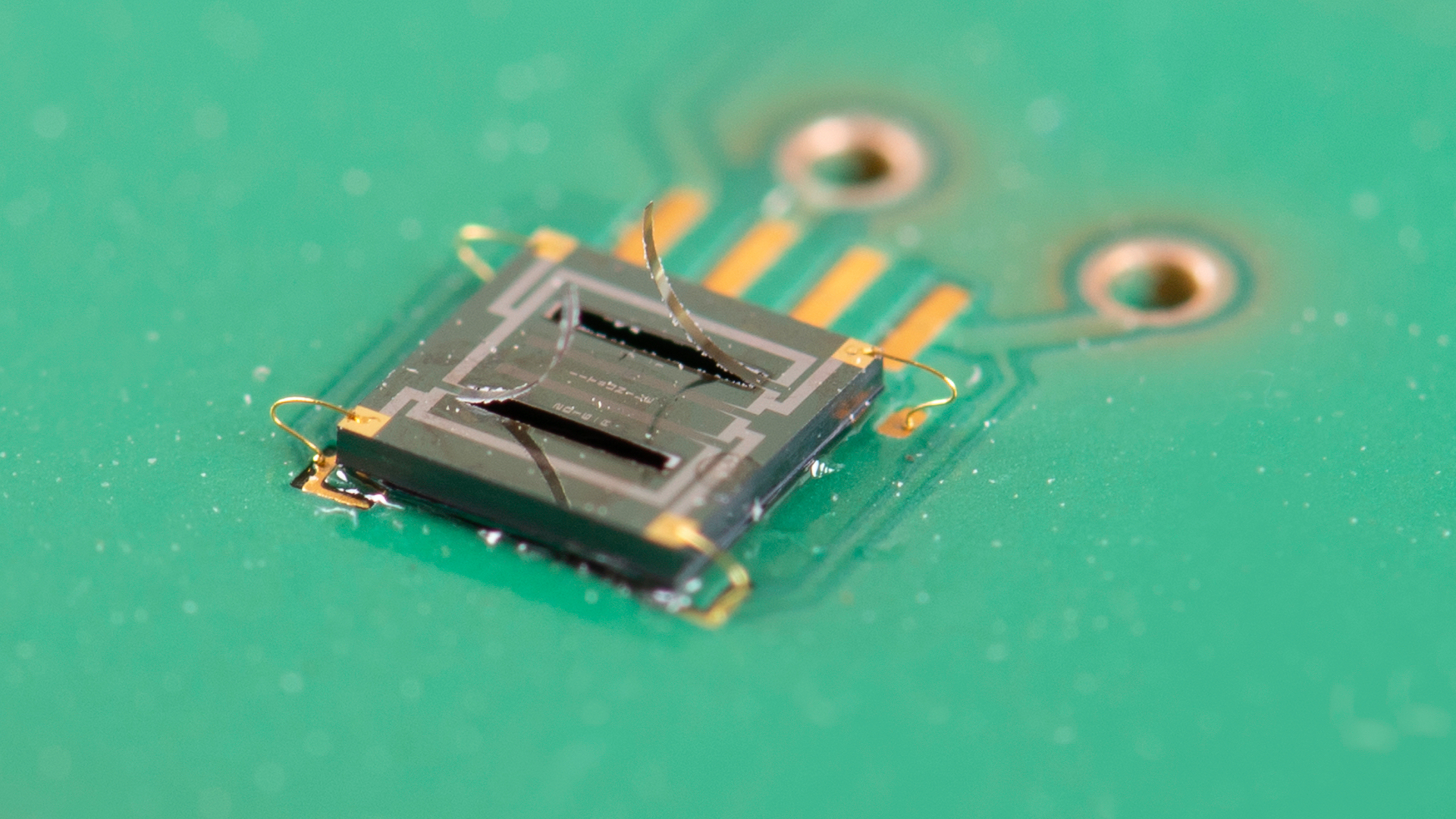

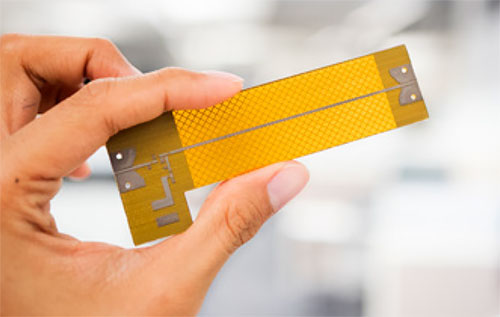

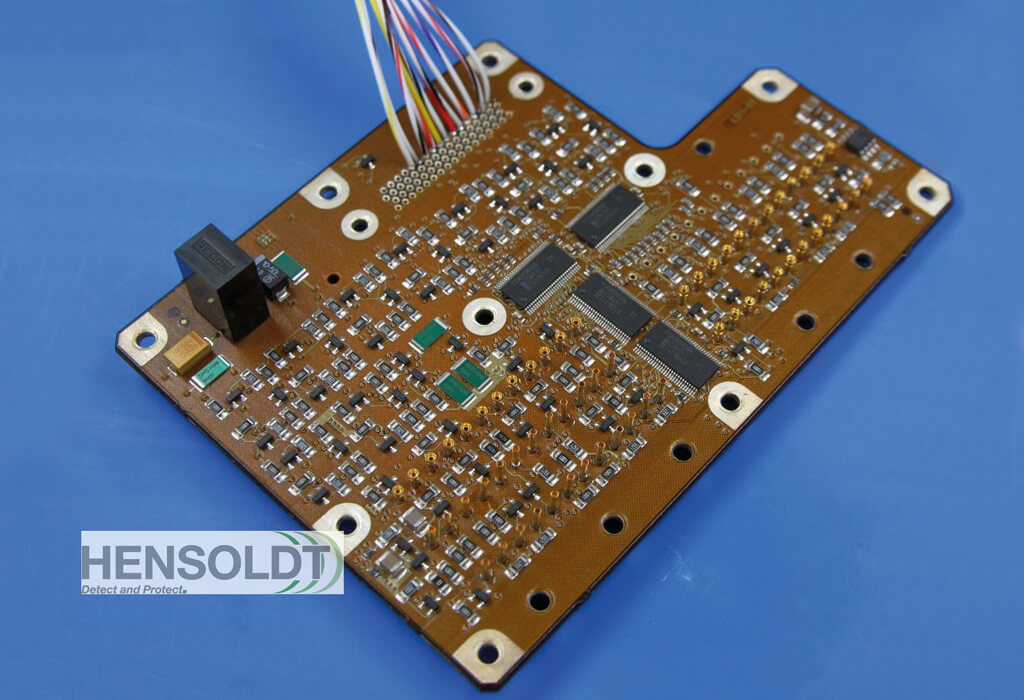

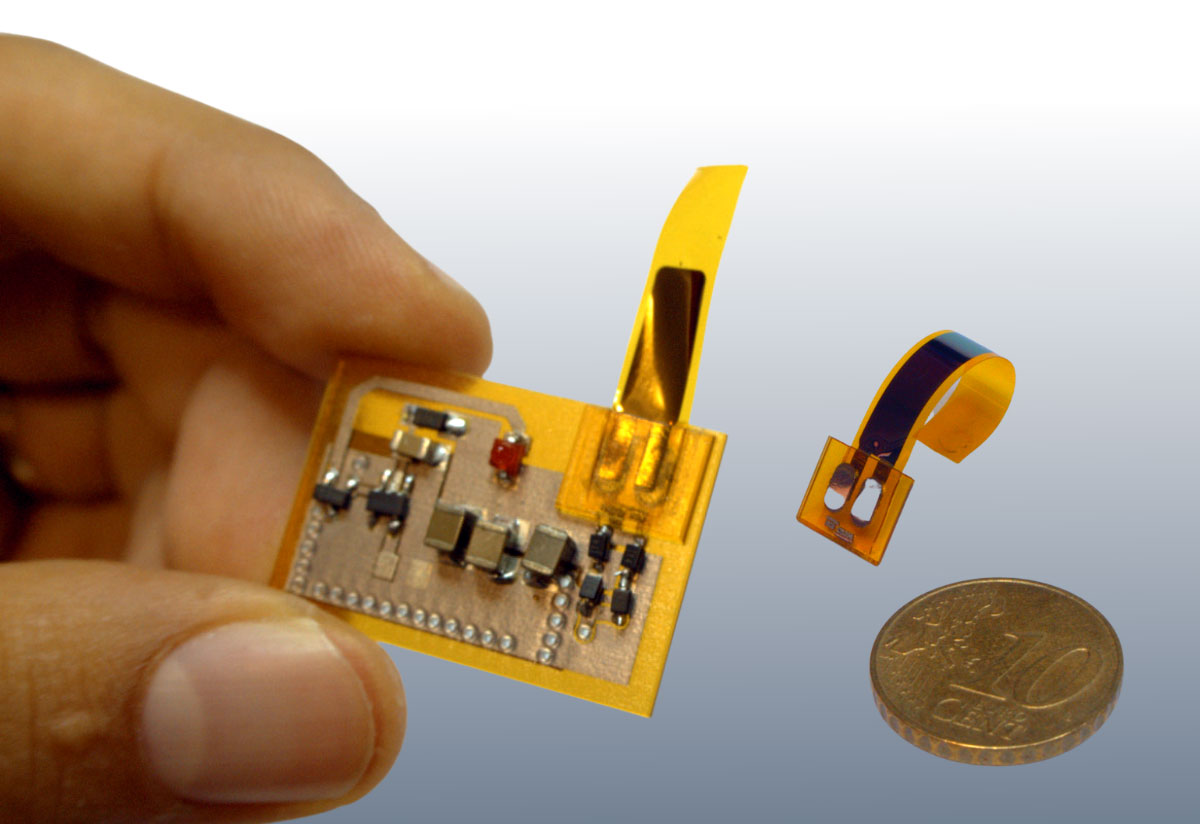

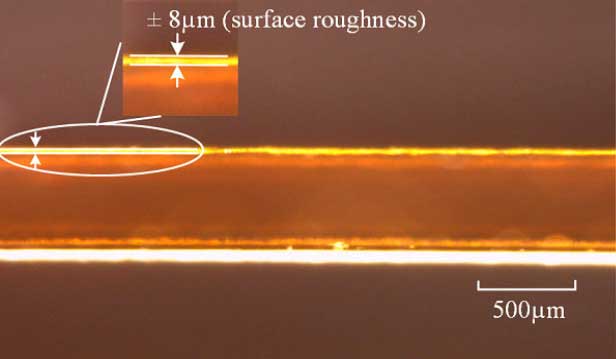

This paper presents a few single-substrate multi-metal layer antennas using additively manufactured

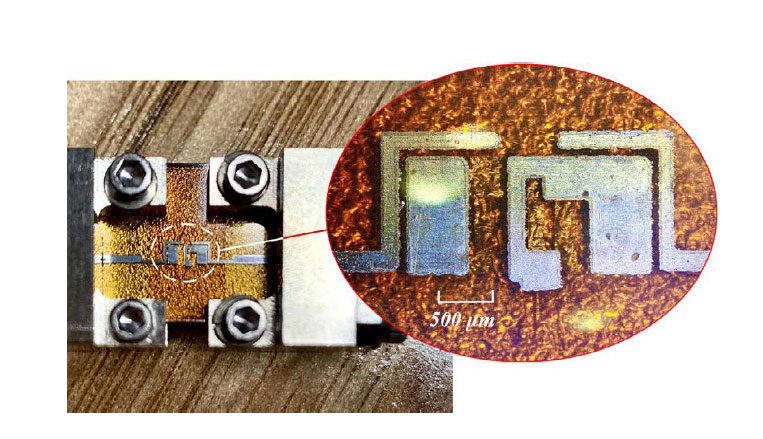

electronics (AME) solution based on piezoelectric additive fabrication. By vertically stacking metal

layers in a 3D printed single substrate, the designed antenna prototype exhibits the advantages of wide bandwidth and ultra-low profile.