Dragonfly™ Materials Datasheet

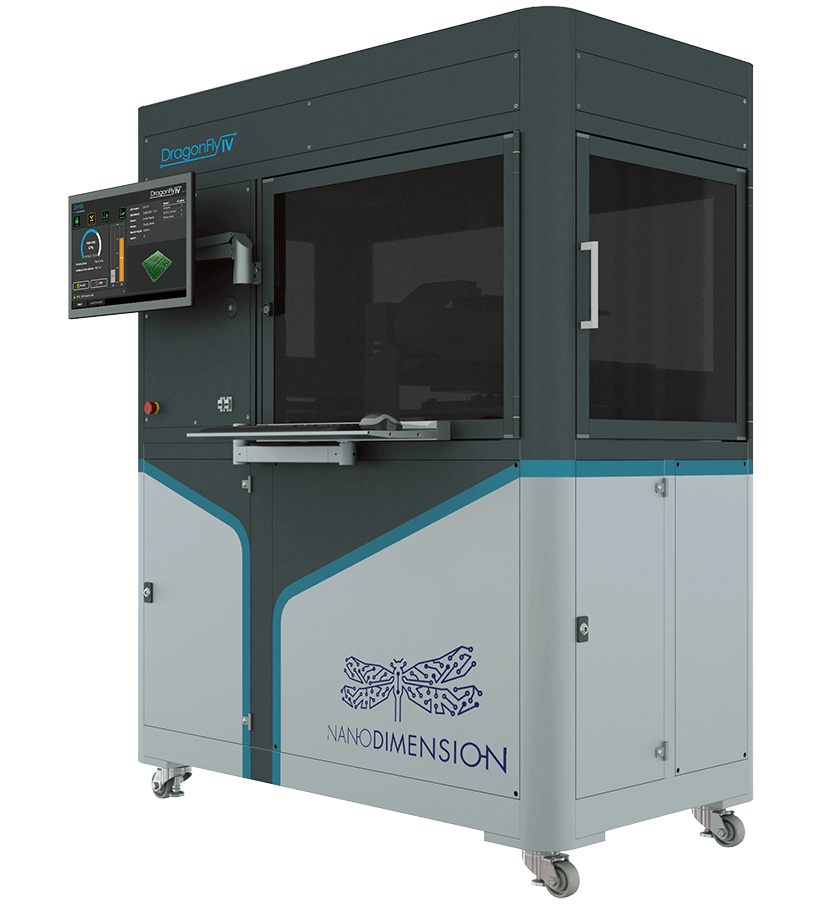

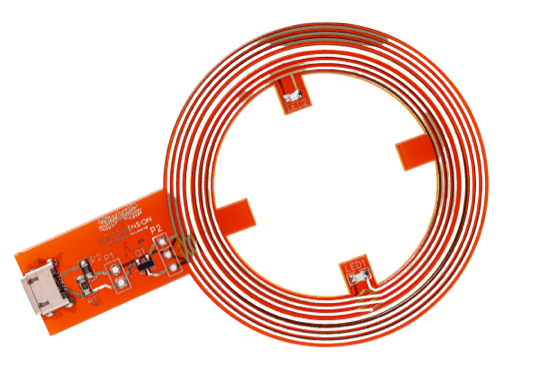

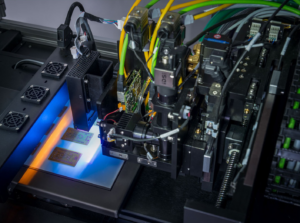

The DragonFly® IV system can print Conductive Ink (CI) and Dielectric Ink 1092 (DI) simultaneously to enable the production of Additively Manufactured Electronics (AME) and HiPED (high performance electronic devices). Click to read.

Get to know the barrier-breaking inks developed especially for the DragonFly™ platform

____________________________________________________________________________________________

AgCite® Silver Conductive Ink

Our formula of silver nano-particles are optimized for sintering and curing.

Tightly Controlled Particle Sizes

Pure silver particles of 10 to 100 nanometers maintain highly predictable conductivity in traces as small as 75 μm.

Environmentally Sound

With less oxidation and less toxicity than copper, AgCite™ presents a cleaner industry alternative.

Dielectric Polymer

Our proprietary dielectric material provides both insulation and structure.

Stability and Durability

Our UV-curable acrylate ink is ready for application in a wide range of industries.

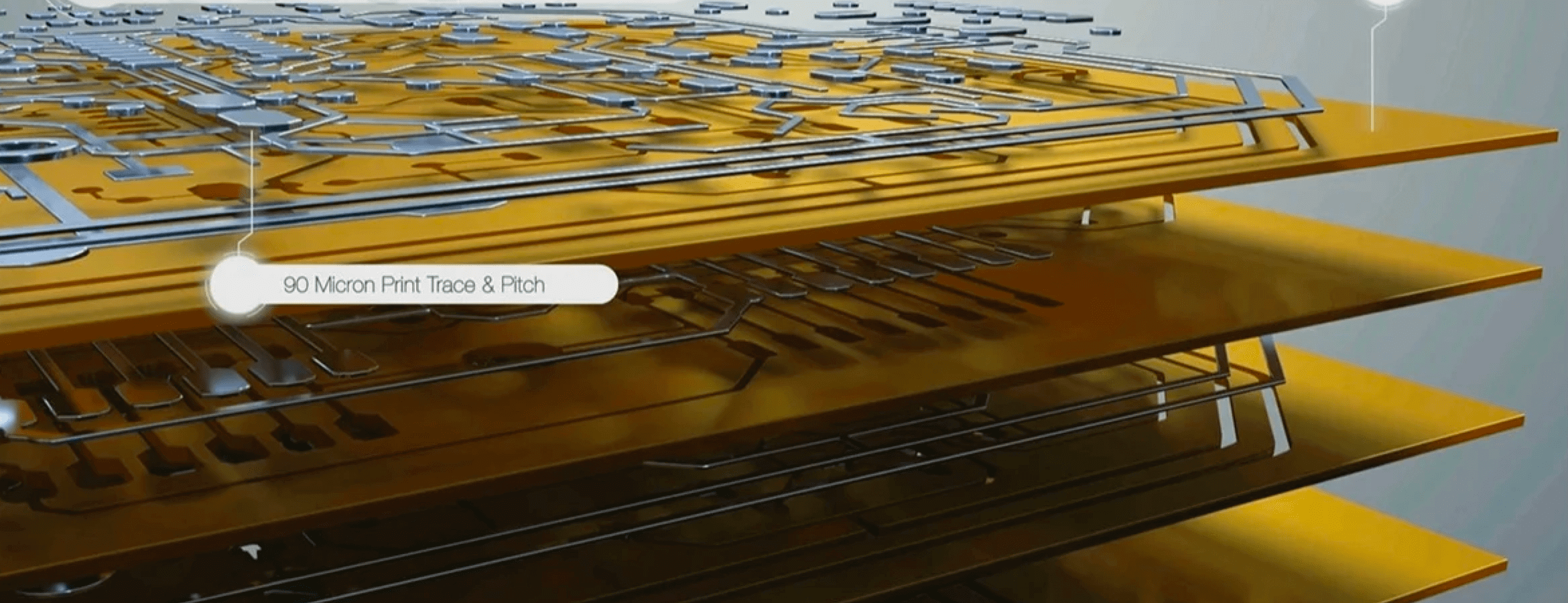

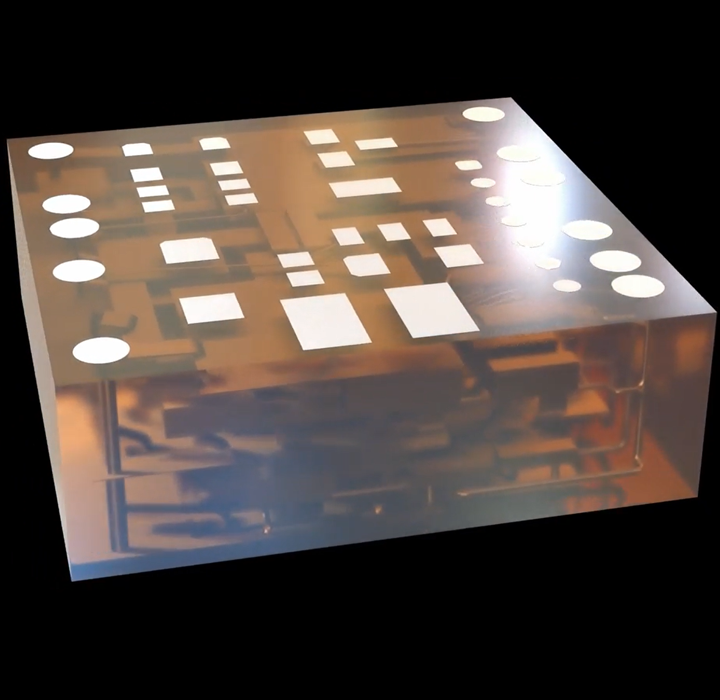

High Resolution

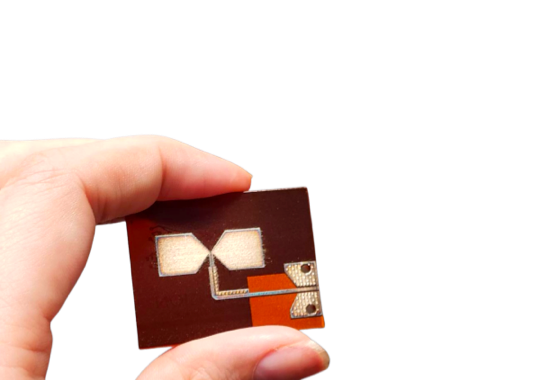

Allows the creation of 3D printed High-Performance Electronic Devices (HiPEDs) with 18µm resolution.

Unique Compatibility

Together these advanced formulas solve the biggest obstacles to print complex circuit boards with speed and precision.

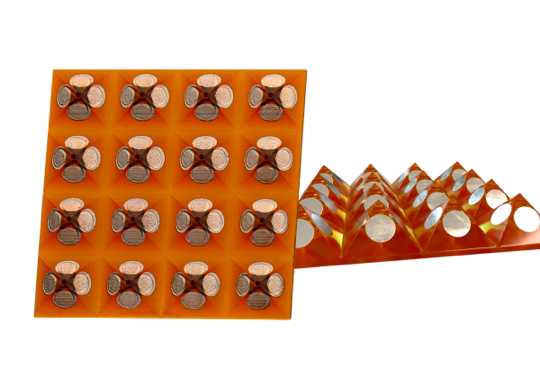

Concurrent Deposition

Both dielectric and conductive inks are simultaneously printed and cured using infrared (IR) and ultraviolet (UV) systems.

Little to No Material Waste

In contrast to traditional PCBs, the inks for DragonFly generate negligible waste and are recyclable.

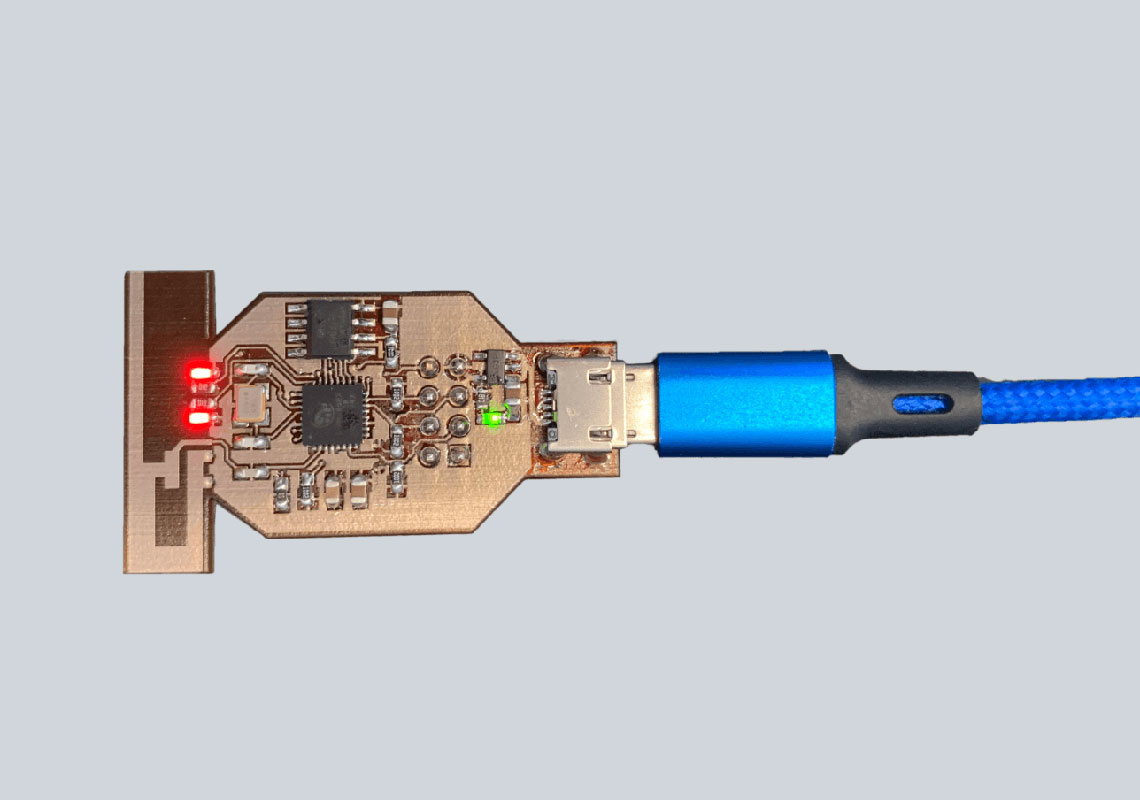

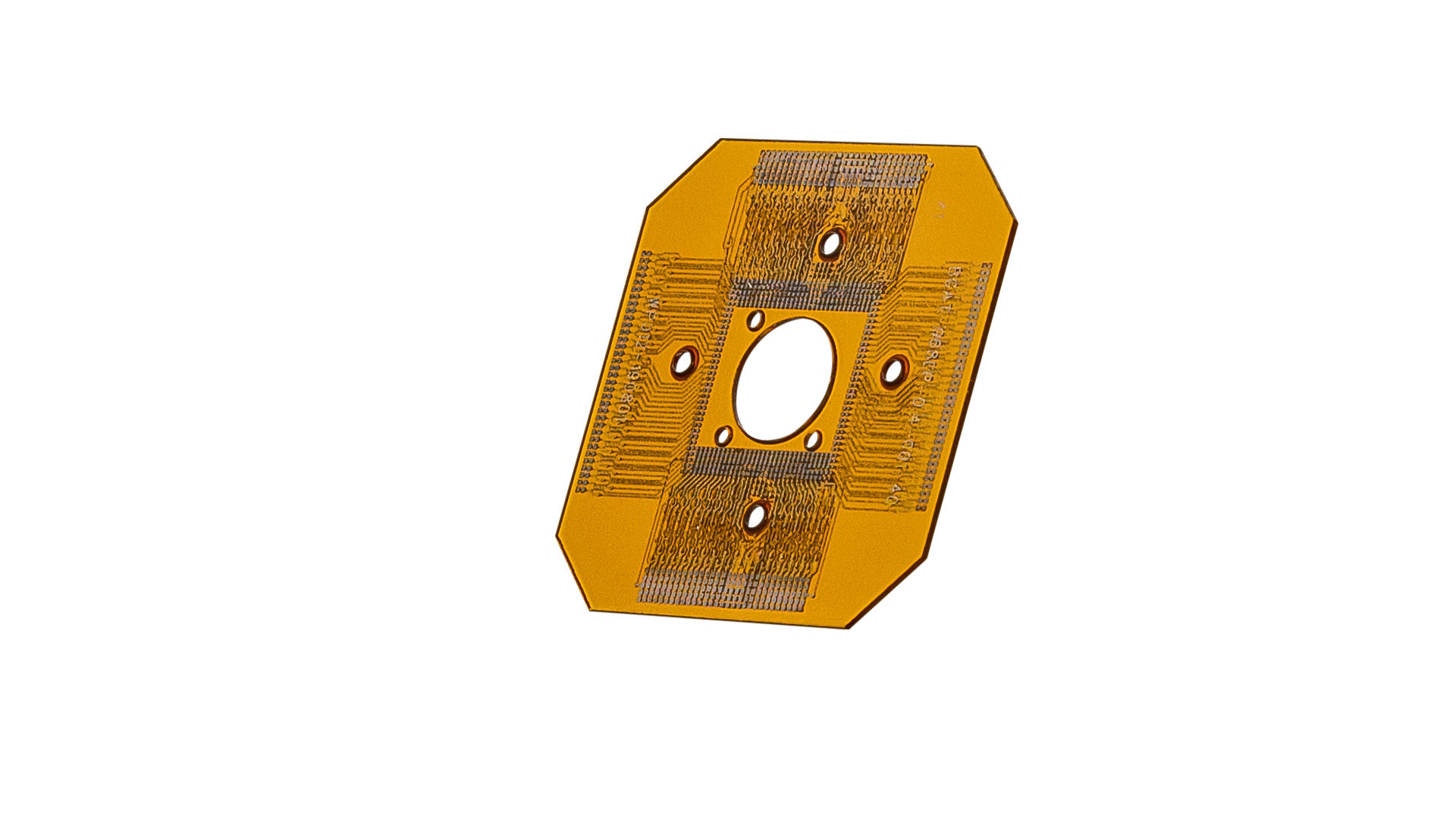

Successful Hi-PED reliability performance based on IPC-650

· IST (Interconnect Stress Test) over 300 thermal cycles in the range of RT (Room Temperature) to 100°C

· HATS (Highly Accelerated Thermal Shock) over 500 thermal cycles in the range of 0 to 70°C

· Mechanical shock (TM 2.6.5) and Vibration (TM 2.6.9) (Hi-PED dimensions: 80 x 60 x 1.6 mm3)

_