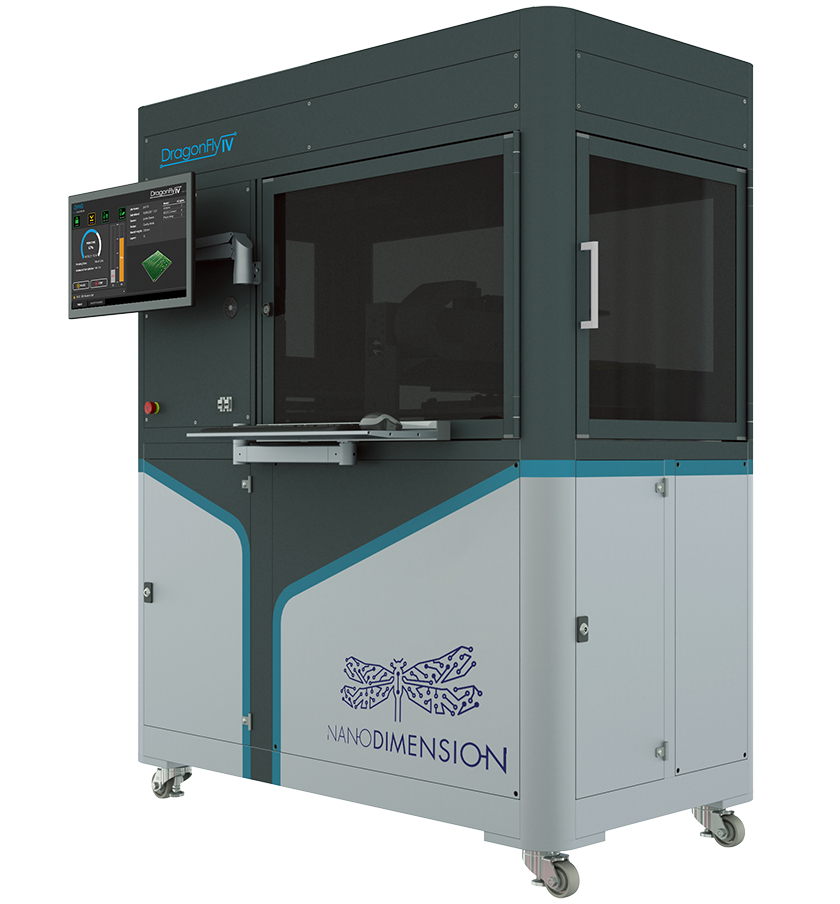

DragonFly IV + FOX

Maximize your budget with the ultimate AME Defense Solution

Inhouse Prototyping of PCB + PCBA (SMT) our most cutting edge combo system

The DragonFly-Fox combination of systems provides an end-to-end solution that leverages proven technologies and excellent application engineering support to enable the U.S. Department of Defense and approved contractors the ability to rapidly prototype complex PCB/PCBA with unlimited layer count, advanced RF/HF, sensors and components, in new and innovative form factors, all in-house to ensure IP protection.

- Leading organizations around the globe place their trust in Nano Dimension Solutions

- US Department of Defense certified vendor

- ITAR – International Traffic in Arms Regulation

“The ability to manufacture RF systems in house offers an exciting new means for rapid and affordable prototyping and volume manufacturing.”

Dr. Arthur Paolella,

Senior Scientist, Space and Intelligence Systems, L3 Harris Corporation.

“Nano Dimension’s AME technology helped us to achieve an original product prototype and it simplified the manufacturing process compared to traditional methods.”

Dr. Francesco Guido

CTO Piezoskin S.R.L.

“To have high-density components quickly available with reduced effort by means of 3D printing gives us a competitive edge in the development process.”

Thomas Müller

CEO of HENSOLDT

“The ability of the DragonFly system to rapidly and affordably manufacture functional prototypes makes it ideal for our team.”

Prof. Massimo De Vittorio

CBN-IIT — Lecce — Italy

Our combo package Fox + Dragonfly creates the ultimate defense solution

Fox

- Combined place & dispense processes

- Small footprint

- Expandable in any direction

- Mineral cast chassis

- Nonstop feeder & production

- Fast, durable linear motors

DragonFly® IV

- Multi-material, multi-layer printer

- Generates entire circuits

- Ensures IP protection

- Environmentally sustainable

- Designs from concept to validation

- Lowers R&D operation costs

RF Applications

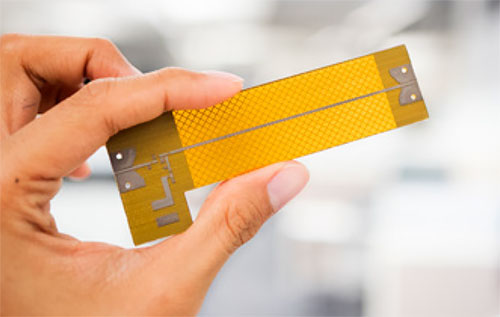

UTS RF Antenna

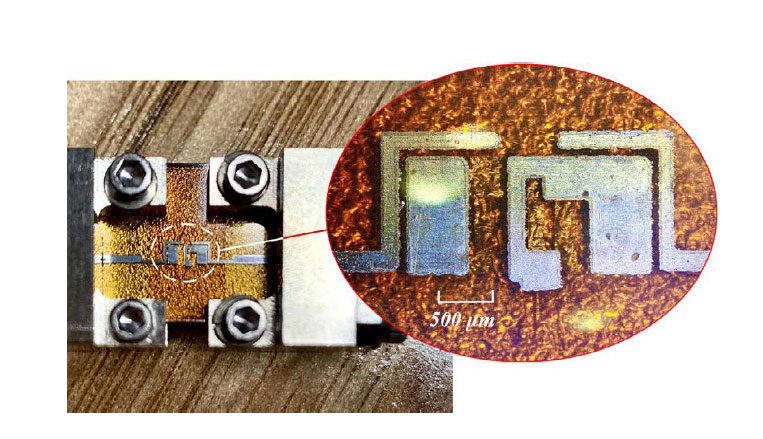

L3 Harris RF Circuit

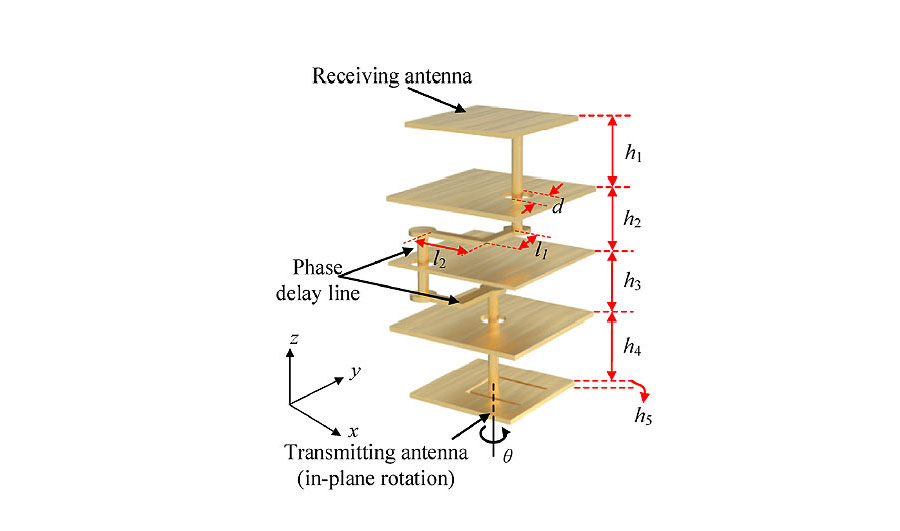

Freznel Dual Frequency Lens for Millimeter wave

Ideal for 5G

3D printed low profile antenna array ushers in a new era of 5G IoT

Small Form, High Performance

3D printed vertical metal layers deliver wide bandwidth and low profile

New Classes of Parts

New beam-forming IP is urgently needed and can only be produced using 3D fabrication.

First In Space

3D printed communications circuit goes to the Space station

Optimum Performance

Monolithic heterogeneous circuit delivers comparable performance to traditionally-produced circuits

Rapid Iteration

Evaluate several design variations at the same time and iterate within hours

Leap in Innovation

Miniaturized packaged arrays that maintain essential performance.

Previously Impossible

Merging of two single-band FZP metalens operating at distinct frequency bands seamlessly into one

Reliable Performance

Radiation performance of the dual-band FZP lens is found to be comparable to that of each single FZP metalens.

Certification and conducted tests

- U.S. Department of Defense Certified Vendor

- ITAR – International Traffic in Arms Regulations

- IPC-TM-650 Method 2.6.5D “Physical Shock, Multilayer Printed Board”1

- IPC-TM-650 Method 2.6.9B “Vibration, Rigid Printed Wiring”1

- IPC-TM-650 Method 2.6.26A “DC Current Inducted Thermal Cycling Test” / IST

- HATS – Highly Accelerated Thermal Shock2

- RTCA/DO-160

- ISO 9001

- ISO 45001

- RoHS