Nov 26, 2019

The Dutch Ceramic Association Works With Admatec

Formatec manufactures products of technical ceramic material, such as alumina, zirconia, and silicon nitride, but also develops new ceramic materials and feedstocks. Ceramic injection molding (CIM) is the main process Formatec uses to manufacture products.

In a heated compartment, ceramic powder is mixed with a polymer binder into a viscous paste. This paste is then extruded into granules, which are loaded into an injection molding machine. Inside the machine is a screw that pushes the paste through a multi part mold.

With unloading the mold, a green ceramic product comes out. Green is not the actual color, but the stage of the material, as it is not the finished product yet. At this point, the material is still soft enough to adapt if needed through milling, grinding and drilling.

After possible design alterations, the green product undergoes heat treatment in several steps. Firstly, a part of the binder is removed to create porosity, so that at the next step with burning out the polymer, the burning gasses can get released.

Depending on the type of the binder, this is possible with water, heat or formaldehyde. The binder had its use during the forming stage, but now it is not useful anymore. The next step is, that the ceramic granules (3-4 micron) of the product are baked together at temperatures far above 1000°C. During this process, sintering, the product obtains its final strength and properties as the granules are connected to each other. Solid dust diffusion of the atoms is responsible for this.

But there is more happening: the space between the granules disappears, causing the product to shrink – up to 30 percent. This is something to take into account earlier on in the process, when making the injection mold design, by increasing it with the same percentage.

After sintering, post-processing can be performed where the product for example is grinded or polished to obtain the desired exterior. The technical ceramic products are functional on the one hand – wear-resistant, inert and able to endure extreme heat.

Formatec is prepared for the future with their R&D activities. Harrie explained about combined injection molding of two different colored ceramic materials where the right heat treatment for burning out the binder and the sintering needs to be found. Also the development of ceramic components with very highly accurate measurements has the attention, such as micro-components with holes of 125 micron and a tolerance of 2 micron. With the electrical properties of ceramic materials, tests are performed to enable spark erosion as processing technology, or to retrieve zirconia with beneficial properties to enable safe electrostatic discharge.

A final development is metal injection molding (MIM) of molybdenum and copper as sister product of the ceramic injection molding process as described. Loran Mak told about the history and current activities of Admatec Europe. The company is derived out of a project in 2012 between the energy research center of the Netherlands (ECN) and Formatec Ceramics about additive manufacturing of ceramics. ‘Additive’ means that you make products by building a product layer-by-layer.

Especially suitable if you want to make products relatively fast and customized, without (much) material loss, but with a lot of design freedom. Another name used for Additive Manufacturing is 3D printing.

DLP 3D Printing

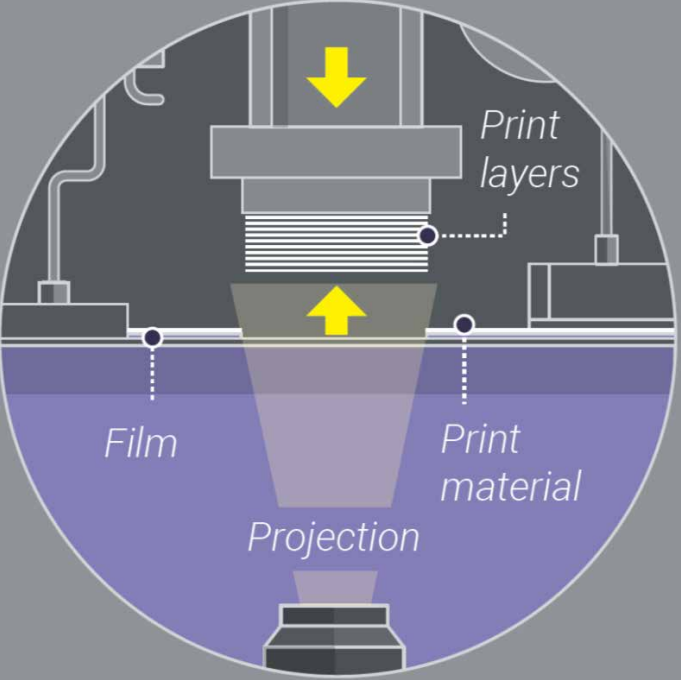

To print ceramic or metal products, Admatec uses Digital Light Processing (DLP), a manufacturing technique based on stereolithography. With DLP, a ceramic or metal powder is mixed with a liquid polymer sensitive to UV light. In the printer, a thin layer of highly viscous printing resin is loaded onto plastic foil, a process similar to tape casting.

A 3D model file of the print is generated with CAD-software and sliced into layers of approximately 50 micron each, which is uploaded to the printer. After this the actual -indirect- printing starts. During each step, the printer head moves downward, pressing the printing resin on the foil. From underneath, LED light illuminates the exact pattern per layer and cures the UV sensitive resin.

After the layer is cured, the printer head moves upward and the foil with resin moves along to ensure new and uncured resin is available for the next layer. This process repeats until the entire product is printed. The 3D printed green object now goes into a furnace to remove the cured UV-sensitive resin, followed by going into a sinter furnace. There is a certain analogy between injection molding and DLP, because both forming technologies each in their own way are followed by a sinter step to obtain the final product properties of the object.

Typical materials Admatec is printing, are alumina, zirconia, fused silica, stainless steel 316L and copper. You can think of applications such as electrical isolators, specially formed heat exchanges within the process industry, parts for high tech mechanical engineering, motor/turbine parts for aerospace industry, but also consumer goods like parts for a hearing aid.

Pablo González from Admatec went into detail about research on ceramic biomaterials with functionally graded ceramics. With additive manufacturing, as objects are printed layer-by-layer, you can determine variation per layer to obtain a gradient in the structure of the object.

This way, for example, a product can be obtained with a closed exterior while the interior is porous, just like the structure of your bones. By playing around with the porosity -size and shape of the pores- you can retrieve variations in strength and the extent to which cell growth preferably takes place in the sponge-like bone tissue. Several biomaterials are research topics, such as alumina and hydroxyapatite.

By following the, among others, released inflammatory substances over time, preliminary results of a case study show that implants made of hydroxyapatite through additive manufacturing are (at least) comparable to those made more conventionally. After the presentation a tour of the Formatec and Admatec labs followed and the day was closed off with a dinner in Hilvarenbeek.

Microreactor / Heat Exchanger Example

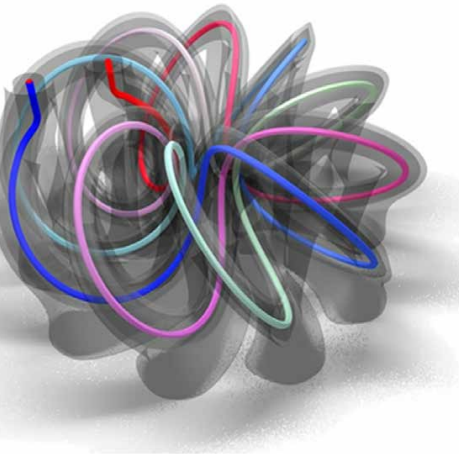

Admatec is proud of their combined microreactor/ heat exchanger in technical ceramics. This ceramic component is designed and optimized using computer simulation (Autodesk Within) for application as static mixer with optimal blending- and cooling possibilities.

In this miniature chemical factory two fluids are injected that undergo an exothermic reaction. The geometry of the reactor however, as it is generated by computer simulation, was so complicated that it could not be made through traditional forming techniques.

Therefore, Additive Manufacturing following DLP principle was the only possibility. But it became even more difficult: the designed channel length and diameter could only be obtained with a raw material that could be rinsed out after printing.

Powder as raw material would clog the channels and could not be removed. However, a ceramic slurry with optimized viscosity was possible to wash out after printing. DLP also turned out to enable delivering the required smoothness on the surface of the microreactor.

Stay Updated

Be informed of the future of additive manufacturing &

3D printed electronics